Education

Lasalle College of The Arts

Aug 2013 to June 2014

BA (Hons) in Fine Arts (Awarded by Goldsmiths U.K.)

Aug 2010 to June 2013

Diploma in Fine Arts (Photography Art)

Documentation for Foundation Studies Exhibition 2010

Design Poster for Foundation Studies Exhibition 2011Collaborated with 2 lecturers for the Lasalle Student-Lecturer Exhibition 2011

Raffles Design Institute

Jan 2009 to Sep 2009

Studied Graphic Design

Temasek Polytechnic

Dec 2004 to Dec 2005

Studied Mechatronics

ITE MacPherson

Jan 2003 to Dec 2004

NITEC in Mechatronics

Work Experience

SPT ASIA Pte Ltd

June 2020 to Mar 2022

Machinist

Conceptualise, design and build a working prototype for automating the X/Y axis on the current EDM machine

Harry’s International Pte Ltd

Nov 2018 to June 2020

Permanent Part-Time Staff

The Great Escape

Oct 2017 to Oct 2018

Bar Manager

Made a month sales on the final Friday and Saturday of operations

June 2017 to Oct 2017

Part-time Staff

Popular e-Learning Holdings Pte Ltd

Oct 2015 to Nov 2017

Freelance Media Trainer

Wow Education International Pte Ltd

May 2015 to Dec 2015

Part-time Media Trainer

Park @ Holland Village

Mar 2015 to Oct 2017

Part-time Barista

CreativeBits

Oct 2014 to Nov 2017

Freelance Media Trainer

Lussoz

Nov 2011 to Feb 2012

Intern Produce Photographer

Setup Photography Department

Art

Singapore International Festival of Arts (Singapore)

17 May to 2 June 2018

The Lapse Project as INTER-MISSION

Still Life with The Artist Village (Singapore)

6 Apr – 15 Apr 2018

Still Me

Metagraphy (Taipei, Taiwan)

11 Dec 2017 – 13 Jan 2018

At 200 Feet

Singapore open Media Art Festival 2017

(Seoul, South Korea)

16 Nov – 30 Nov 2018

At 200 Feet

Metagraphy (Singapore)

11 Nov – 26 Nov 2017

At 200 Feet

Performance Art Resource Orchestrator (Singapore)

6 Jul – 9 Jul 2017

Viralocity 2.0 as INTER-MISSION

INTER-MISSION X IAFT 16/17 (Singapore)

19 May 2017

At 200 Feet

19 May 2017

Viralocity 1.0 as INTER-MISSION

INTER-MISSION X BLACK-HUT (Singapore)

1 Feb 2017

INTER-MISSION X BLACK-HUT as INTER-MISSION

Interdisciplinary Art Festival Tokyo 16/17 (Tokyo, Japan)

25 Nov 2016

INTER-MISSION

Asia Kula Kula-Ring (Gwangju, Korea)

Over and Over

Osmosis Audiovisual Media Festival (Taiwan)

18 Aug – 4 Sep 2016, Taipei

R.T.T.P. (Fading Flats)

20 Aug 2016, Taipei

With Urich Lau, Yue Han and Lim Shengen

28 Aug 2016, Kaohsiung

With Urich Lau, Yue Han and Lim Shengen

Betwixt Festival ArtScience Late – Interstice: Imageries &

Bodies (Singapore)

25 Feb 2016

Video Conference: Co-Optive with Urich Lau and Yue Han

Singapore Open Media Art Festival (Singapore)

29-31 May 2015

R.T.T.P.

(Com)tempoary Osmosis 2015 (Taipei, Taiwan)

22-29 Mar 2015

R.T.T.P.

Digital Art Week; Off Label (Seoul, Korea)

10 – 11 Oct 2014

R.T.T.P.

The Artist Village SHOW (Singapore)

26 Nov – 10 Dec 2013

Book Cover

COS•MO (Singapore)

8 – 24 Nov 2013

Pinhole Recording

Production Team

Noise Singapore 2013 (Singapore)

27 July2013 – 14 Aug 2013

Time

The Story of The Creative (New York, USA)

25 July 2013 – 10 Sep 2013

King Kong series

Picnic Serangoon (Singapore)

13 April 2013

Video Car 2013 With Urich Lau

Closure Artshow (Singapore)

12 Jan 2013 – 17 Jan 2013

Last Look Around

.MOV <Red Dot> Monthly Open Video (Singapore)

Vanity

Lasalle Student-Lecturer Exhibition 2011 (Singapore)

Stormspotters with Lim Shangen, Nissel Yu

and Charmaine Ong

Orbital Cinema with Urich Lau and Yue Han

Lasalle Foundation Studies Exhibition 2011 (Singapore)

Vanity

Prototype for X/Y Axis

Why

- The process has not changed since it was brought into Singapore

- Increase the productivity of both the process and the operator

- Reduce alignment time

- Remove the need of the operator for alignment

- Operator will be able run more machine (large wire) and focus more on in process inspection

- Increase productivity by processing while the operator is doing the inspection

- Reduce human error due to alignment error hence reducing material wastage

- Reduce training time for new staff

- Current process is labor intensive

- Increase consistency of the product

- Streamline between shifts

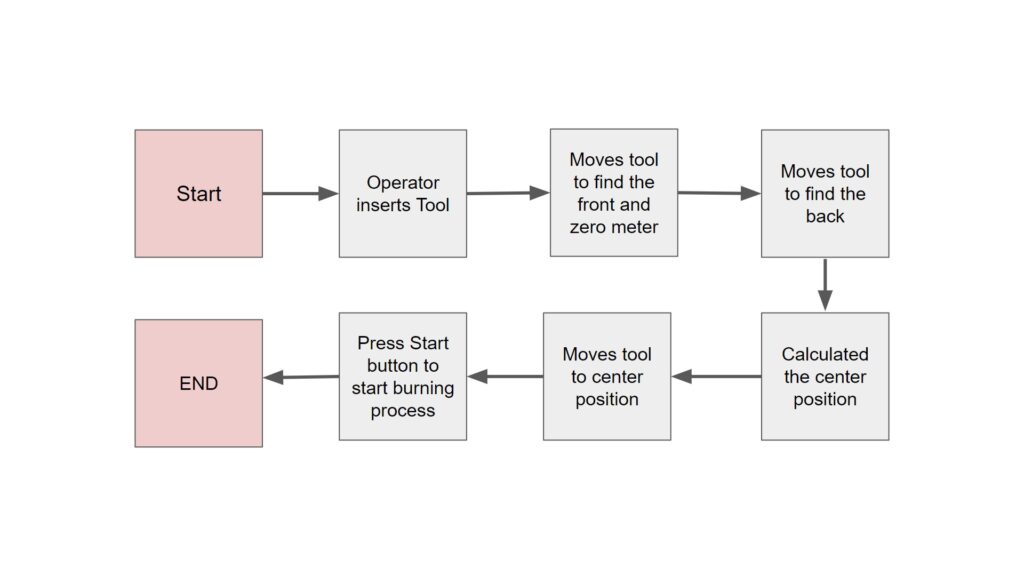

Current Process

Step that the Operator will have to do for every tool.

1. Insert the tool

2. Found the Front

3. Zero the meter

4. Found the Back

5. Do the math to find the position based on the Percentage

6. Move to that position

7. Press the button to the Burning Process

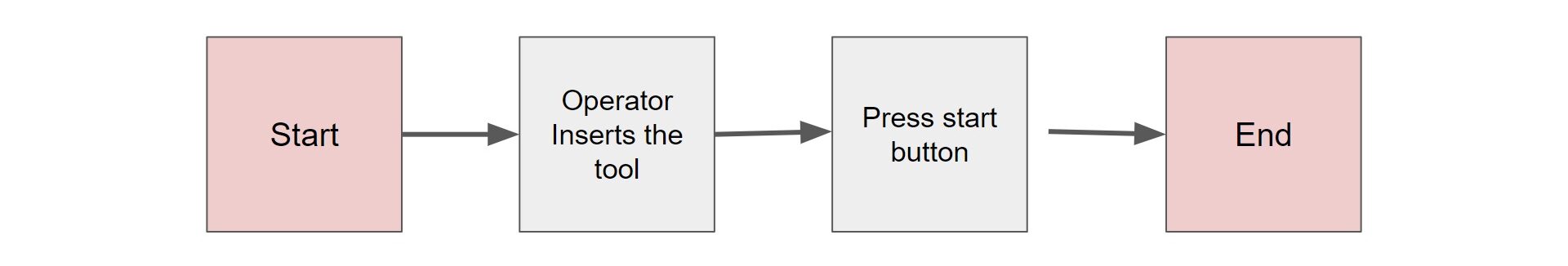

Proposed Process

The Operator will only have to turn a knob to set the write Percentage once at the start of the job.

With this upgrade, the operator will have insert the tool and press the start button.

This upgrade will do the rest

User

- All the operators who are assigned to work on the parts.

- They would have to work on multiple machines/parts as it have a long processing time is long.

- may not be tech savvy

- maybe lazy and do not want to do calculation for every piece.

- There will be some who make mistakes in calculation due to fatigue especially the night shift crew.

Scope, Constraints & Roles

Scope

- Upgrading an outdated machine at minimal cost

- Add automation

- Finding ways to integrate hobby grade components with an industrial machine

Constraints

- Worked on the project without upper management’s knowledge

- Working outside my job scope

- Hobby grade components has different voltage signal with the EDM machine

Roles

- Conceptualization

- Research

- Design

- Coding

- Fabrication

- Testing

Task Flow

Current Operator Task Flow

With the current process, there could be human error especially when the assigned machine is using an analog meter. There will be some guesswork along the measurement process.

CASE STUDY

Part number: 3132349

Description: CKVD-150-WJ-3MM-76MM-G 2024893

Drawing number:2024893

Average burning time: 1min 35sec

Operators running the large wire will always operate multiple machines and when they run tools like these, the machine will always be left idle during process when the operator is attending to the other machine. For this part, they would have to made 3 alignments during the whole process

- First alignment: at the beginning like another tools

- Second alignment: half way through the first impression

- Last alignment: at the second impression before the burning process continues

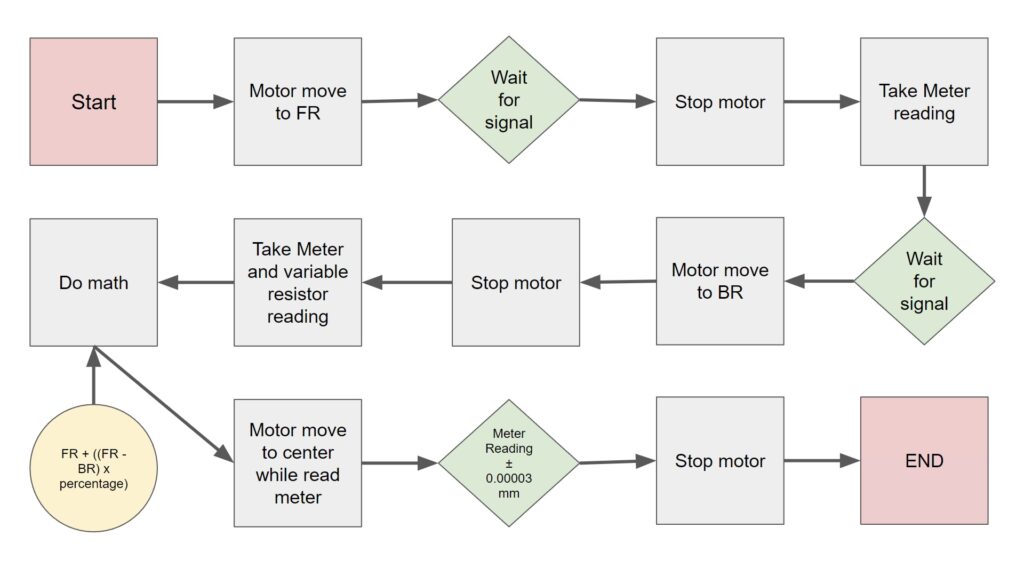

Proposed Task Flow

New operator task flow

The operator’s has been cut down into 2 steps

Program task flow

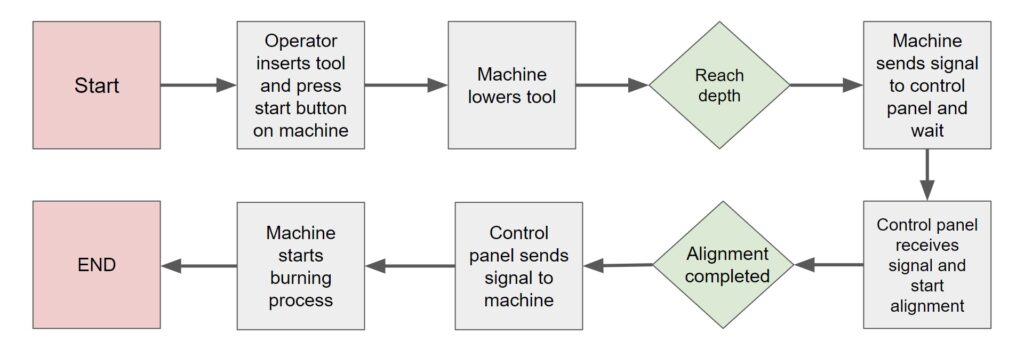

Intergraded with EDM machine task flow

With this proposed, the upgrade will take all guesswork out of the equation as it takes measurements and calculations digitally.

Process

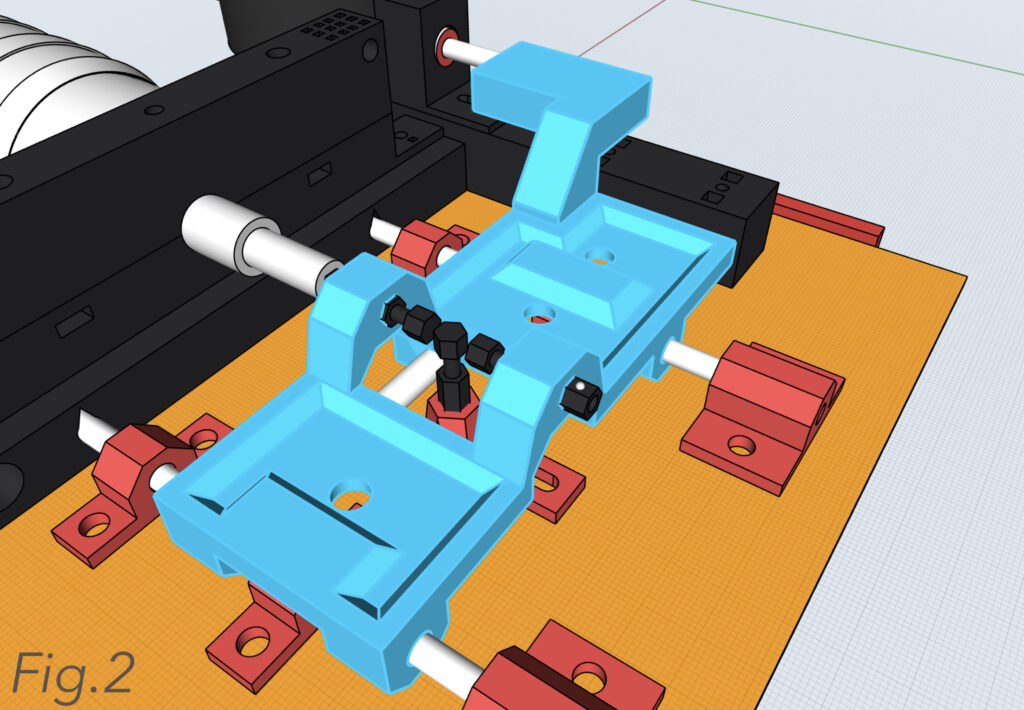

Fig. 2 shows the whole movable bed.

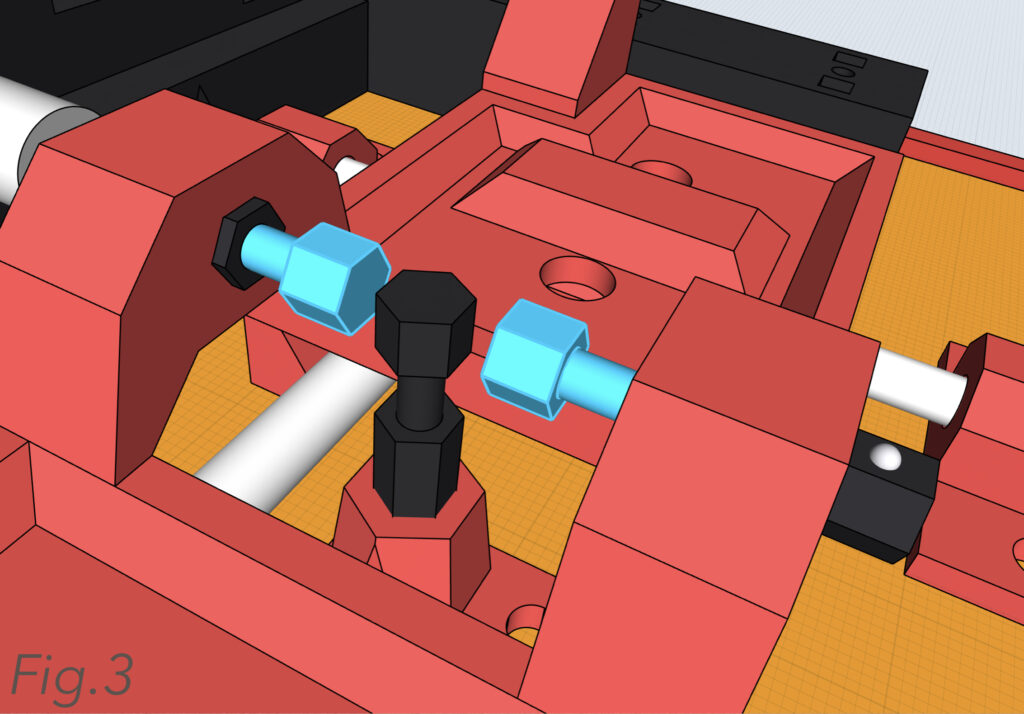

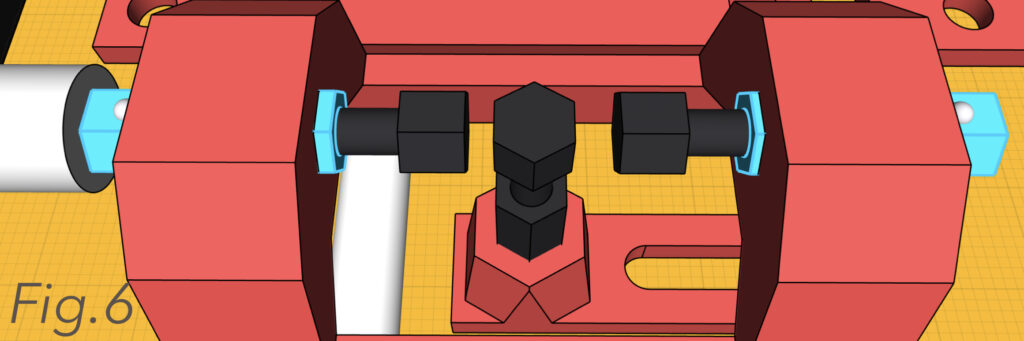

Fig. 3 is hex screws so the size of the gab can be varied

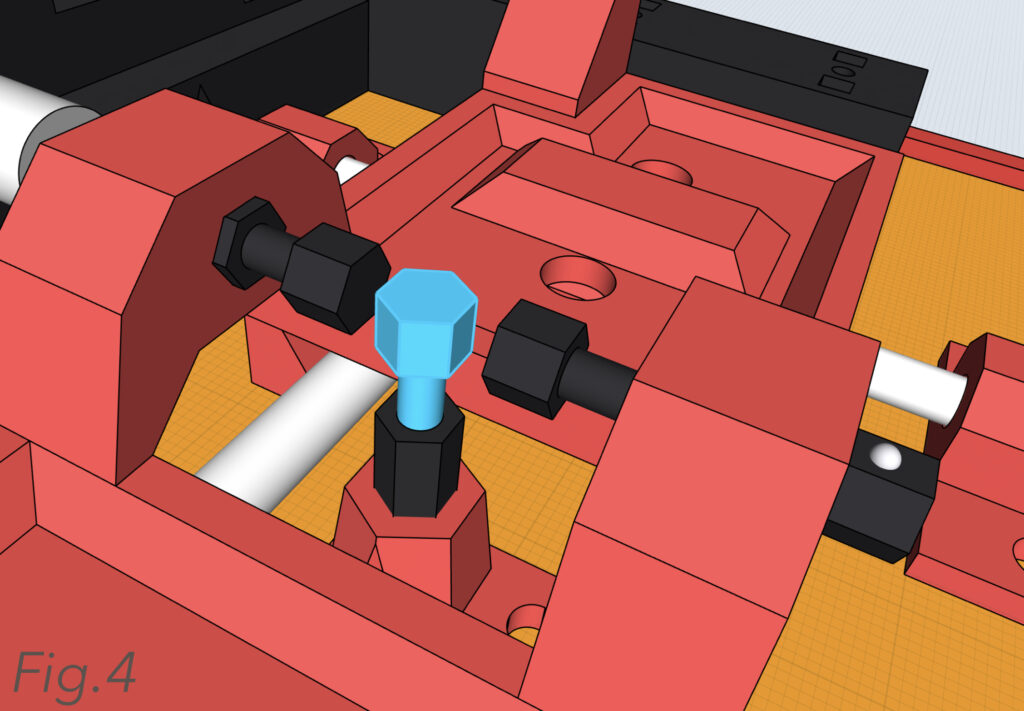

Fig. 4 is a hex screw to simulate the tool and its not movable.

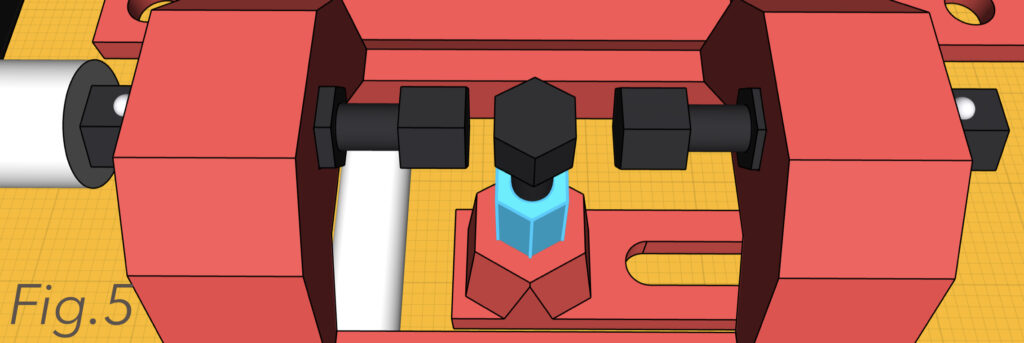

Fig. 5 and Fig. 6 are connection points to get a signal when it touches each other.

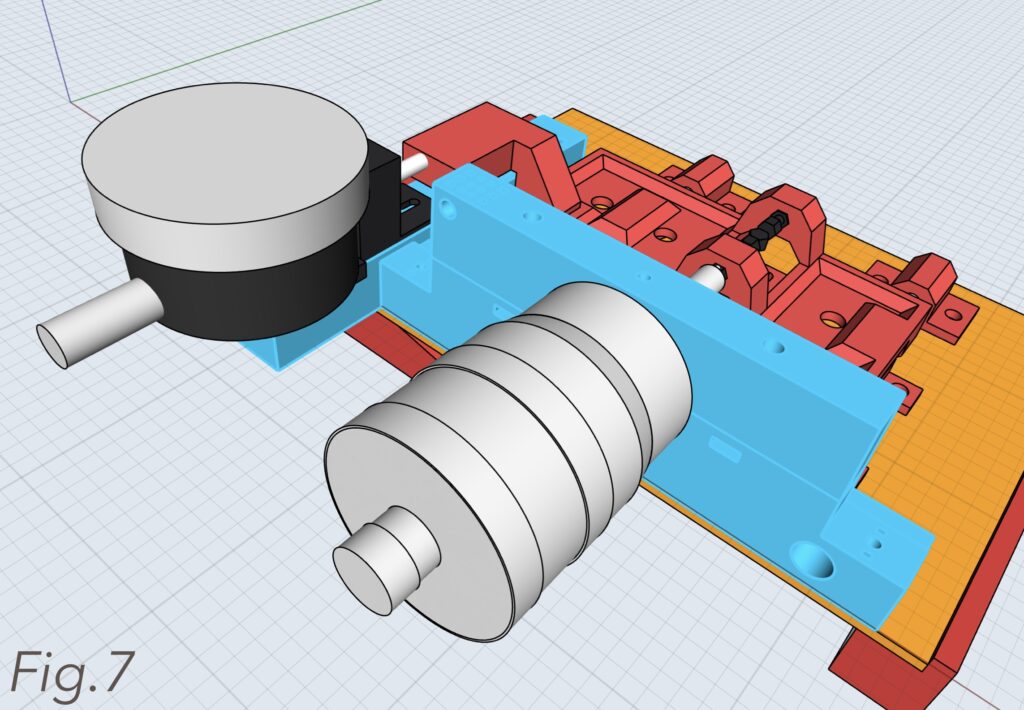

Fig. 7 is modeled at dimension and where the motor will be installed

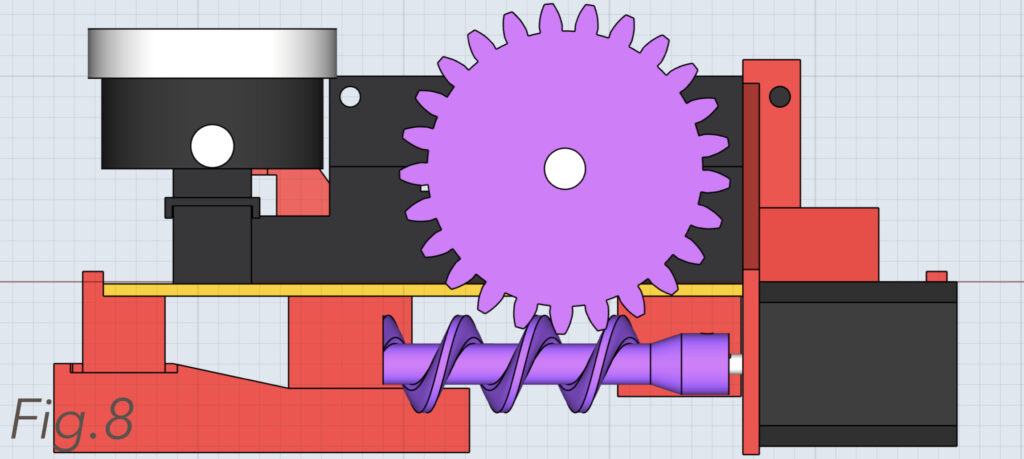

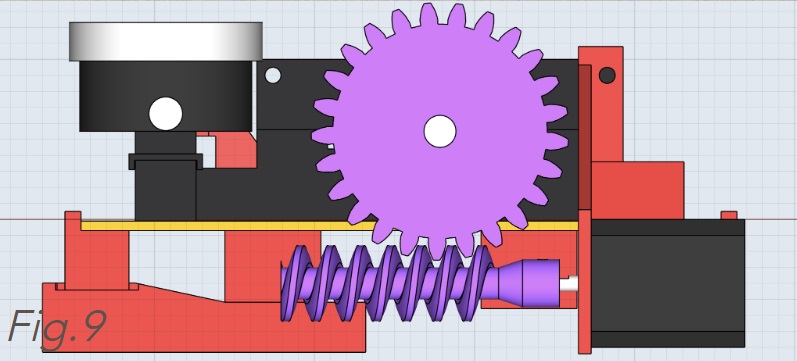

Fig.8 current setup

Fig. 8 and Fig. 9 are different gear ratios (12.5:1, 25:1) there were tested.

The motor chosen was a 5.5kg NEMA17 stepper motor and is programmed to run at 1/16 step to reduce vibration and increase accuracy per step

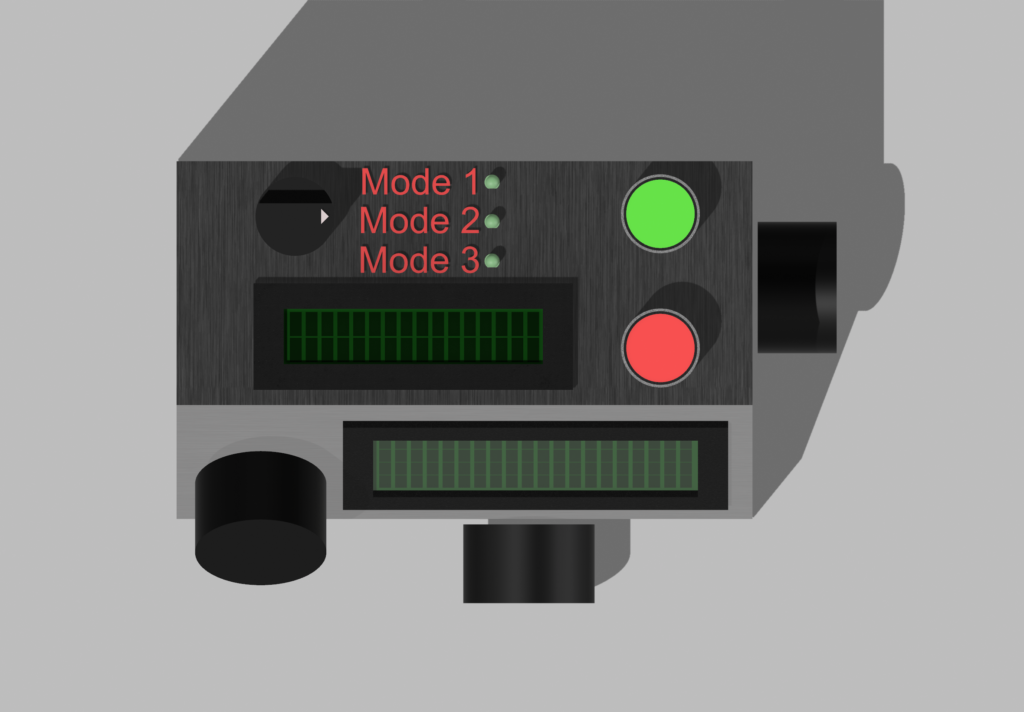

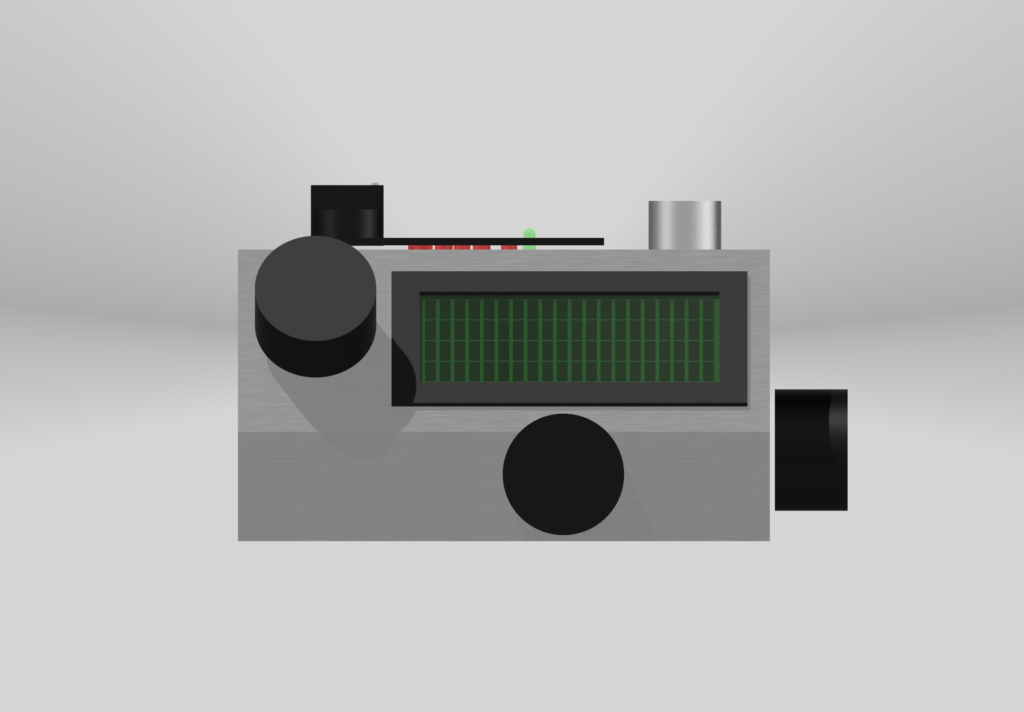

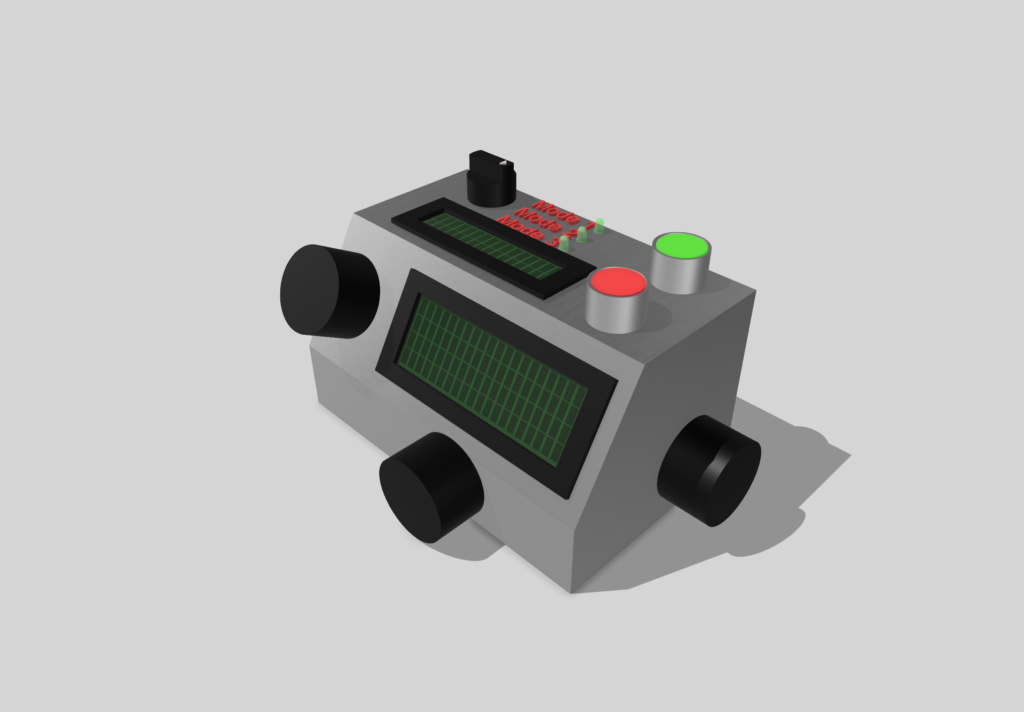

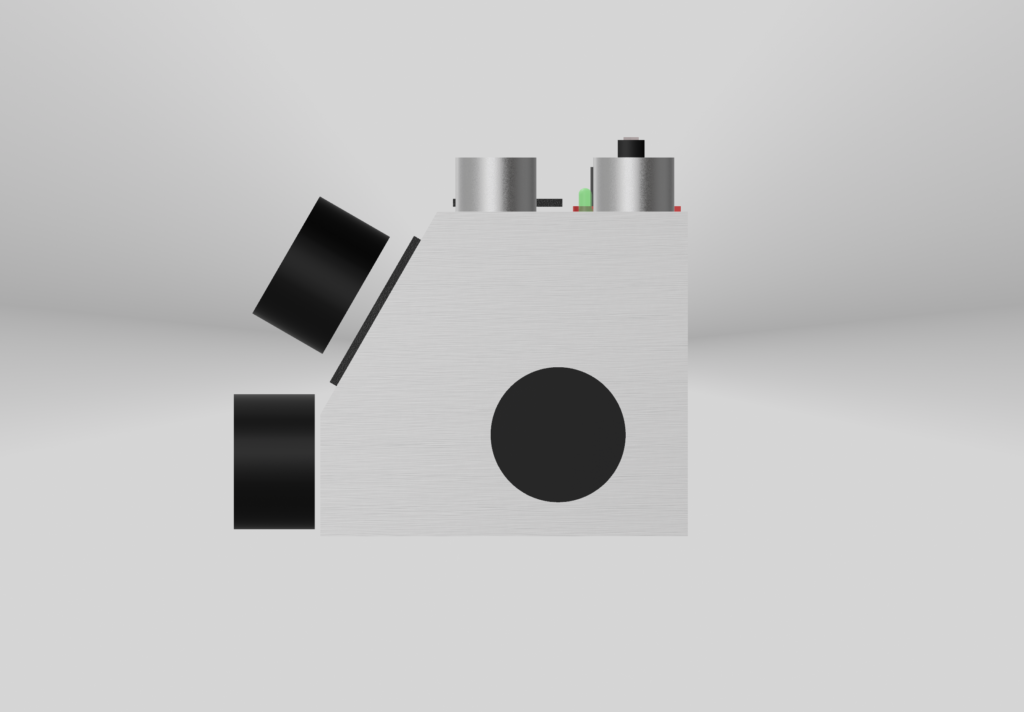

Proposed control panel

Top View

Front View

Isometric View

Right Side View

The control was designed to fit the mental model of the operator.

The knobs at the front and side would be for controls in manual mode and it’s in the same orientation as the machine (Front for Y axis, Right for X axis).

The bigger screen will display measurement readings from both micrometers and the knob at the side is for setting the center position value.

The smaller LCD screen at the top will display the mode it is set to.

The operator can change to different modes with the turn-toggle switch at the top and it has labels at each position of the switch so they will not need to guess or remember which position is what mode. The LED at the side of the label will light up in the selected mode.

The Start and Stop buttons are also placed in a similar layout as the machine’s control.